CASE STUDY DEC 2020: Grease Trap Waste Consolidation Hub

THE OPPORTUNITY

The Netherlands has an established practice of Grease Trap Waste (GTW) collection from collection points in the catering industry. GTW contains a significant portion of oils and fats that can, if adequately separated be used to produce biodiesel. Logistics costs and water effluent management are a main components in the optimisation of GTW collection and processing.

THE PARTIES:

Eco Clarity a privately owned waste to energy service provider, established in 2013, which has developed a patented modular and scalable technology, for the efficient and cost-effective disposal of Grease Trap Waste (GTW). The company has spent almost a decade developing breakthrough technology to transform the wastewater handling process from one of disposal, into a focus of conversion into beneficial feedstocks and clean water.

Argent Energy is a privately owned waste-based biodiesel producer. Established in 2001 and acquired in 2013 by John Swire & Sons (Green Investments) Ltd., Argent Energy has operations in Scotland, England and, since 2018, in The Netherlands. Their biodiesel facility at Ellesmere Port in England pioneered sophisticated pretreatment facilities enabling it to accept a wide range of highly de-graded waste fats, oils and greases before processing them into high-quality biodiesel for the decarbonisation of transport, as well as other industries.

THE SOLUTION

Eco-Clarity Ltd, has developed a “Hub” solution for the GTW separation that is efficient, fully automatic and has a small footprint in physical and energy consumption terms. Eco Clarity and Argent Energy have a shared belief that GTW collection and processing industry wide can improve significantly. Although they are not a fats collector, Argent Energy has enabled Eco Clarity to run trials of its new technology solution at their site in Amsterdam to help demonstrate the reliability and decarbonisation value of this route to biodiesel for processed fats.

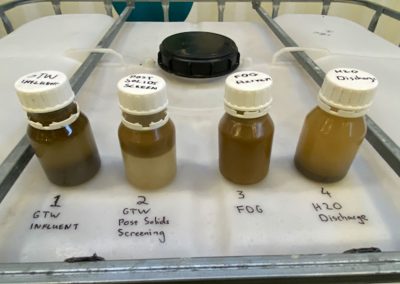

During the trial, GTW collected from the Amsterdam region is discharged and separated at the Argent facility, producing a fraction of Fats, Oils and Grease (FOG) for biodiesel production. Suspended solids are fed to bio gas production and the waste water has a significantly reduced chemical oxygen demand (COD).

Eco Clarity’s Hubs have a small footprint of 10m2, made up of an automated Huber solids screen, two 20’ foot treatment containers, and a 20 foot FOG post processing and storage container.

A standard Eco Clarity GTW Hub, is capable of accepting 10 tonnes of GTW in 10 minutes, with a further 10 tonne truck each 15-20 minutes thereafter. Being automated the system is able to receive waste 24/7. With a quick setup, the Eco Clarity GTW Conversion Hub was ready to process waste within 3 days of delivery.

RESULTS AND BENEFITS

From first 320 tonnes of waste accepted at the Hub, Eco Clarity was able to harvest 30 tonnes of concentrated FOG and FOG containing solids, as a feedstock for biodiesel production, analysis shows that there is 99.99% reduction of FOG within the discharge effluent and an average 30% reduction in COD, with a PH of between 4 to 5.

|

Average Effluent Results |

||

|

PH |

4.8 |

|

|

COD |

9158.3 |

mg/l |

|

Sulphate |

158.8 |

mg/l |

|

Phosphate |

91.3 |

mg/l |

The above table shows the average effluent results, after treatment

The ratio of GTW to de-watered FOG depends on the volume of FOG within the GTW load and where the trucks have collected that day. Some loads may have low volume of less than 2-3% whilst others have as much as 20%.

Within two weeks of operating, Eco Clarity were accepting all the daily loads from the 5 x trucks and during slow periods have started on the processing of materials stored in the local storage tank.

The plant accepts 20 tonnes of GTW per hour and has processed GTW 24/7 when in automated mode. Maximum power consumption when accepting waste is 40kWh, and when in maintenance and harvesting mode it is aproximately 5kWh.

Recent Comments