Robin Hayes, Editor at Cape Business News Writes:

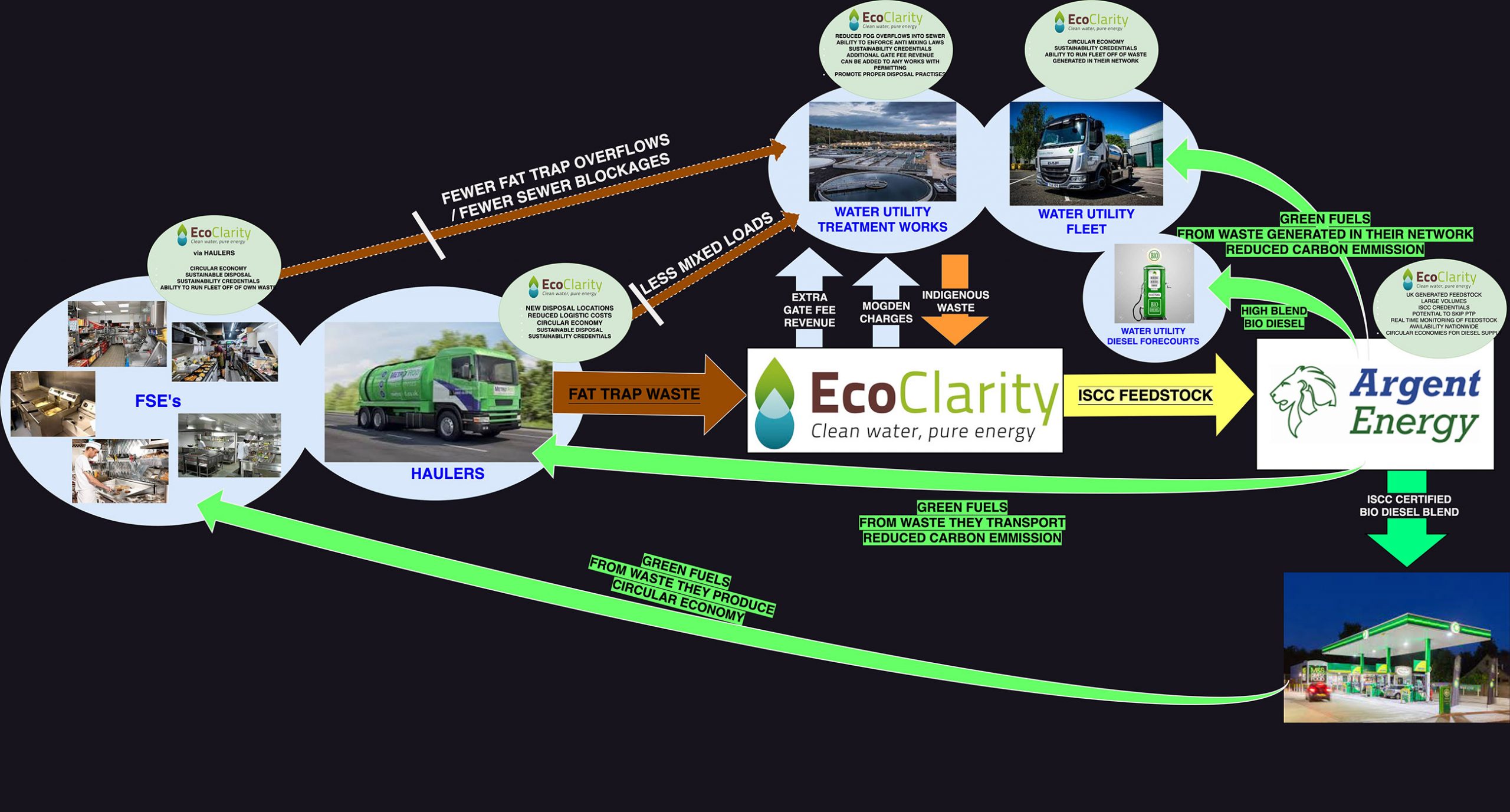

A year has elapsed since the editor interviewed South African entrepreneur Christopher Clemes, who jointly invented and patented the Eco Clarity technology solution in the UK, which separates problematic FOG (Fat, oil and grease) from wastewater. The process recovers a valuable feedstock for the manufacture of biodiesel while returning effectively cleaned wastewater to the waste stream. (See article: Taking the fat out of fatbergs – CBN April 2022 – www.cbn.co.za/online-edition/cbn-april-2022).

Keen to follow the development of this revolutionary system, the editor tracked down Chris Clemes on a recent visit ‘back home’ to the Cape where in addition to some R&R, Chris will be in discussions with personnel from Fabrinox in Paarl, the manufacturers of the containerised Eco Clarity plant units.

Huge Demand

“Since our first pilot plant was set up in Amsterdam two years ago for one of Europe’s largest biodiesel producers, Argent Energy, we have been investing in an R&D phase which has resulted in a third generation plant which was recently installed at Argent’s site in Stanlow, Ellesmere Port in the UK” explained Clemes.

“What we have uncovered is that there is huge demand for our recovery technology. There are about 142 000 food service outlets in the UK, each producing around 140ℓ/month of between 5 – 30% FOG which has to be disposed of in a responsible manner by GTW (Grease Trap Waste) hauliers.

“Our model of placing an Eco Clarity hub at a wastewater treatment site within 1 hour’s drive for the hauliers means that they benefit by completing more trips / day and greater revenue, and for the wastewater utility, the recovery of treated wastewater that previously untreated, could interfere with the biological functions of the plant. In a worst case scenario, illegally dumped FOG from overflowing grease traps causes sewer pipe blockages called ‘fatbergs’.

“The big bonus is that the concentrated FOG – up from an untreated 5%, is now +95% pure and of real value to the manufacturers of biodiesel.

“Our original 50t capacity plant has now been doubled in capacity to 100t with bigger tanks and our fourth generation plants, two of which are currently under construction by Fabrinox, will be delivered to a UK customer by October this year.

Milestone Achieved

“We have now reached an R&D milestone where fourth generation plants can now be considered for commercial manufacture on an assembly line as a fully packaged and guaranteed treatment system. Based on our research and discussions with customers and stakeholders we conclude that it’s entirely feasible to have up to 40 plants operating in the UK and Europe by 2026.

“We have already received offers from water utilities throughout the UK to install Eco Clarity units at numerous sites and enquires are pouring in from Europe, Middle East, India and China.

“Twelve UK GTW hauliers have over 400t of FOG waiting to be processed at any one time and original estimates of 20t/week/plant of pure FOG have been revised upwards to a much higher potential of pure FOG per /week/plant. We have also received enquiries from a number of new potential sources of FOG, for example from sites which are currently spreading to land.”

Local Opportunities.

“In order to meet demand, Fabrinox are ramping up production and envisage a dedicated production line of Eco Clarity units. We are also in discussions with them for greater involvement of their service and facilities such as procurement and installation teams for the UK.

“Under investigation is a solar powered Eco Clarity unit and the original Amsterdam pilot plant is being returned to SA to be used as an R&D test bed as local conditions here are different to those encountered in Europe, with scope for testing for our similar markets globally.

“I have my eye on the first Eco Clarity plant in SA being installed at ‘the restaurant capital’, Franschhoek although we are in discussions with several municipalities in the Western Cape who have expressed interest in the concept” he concluded.

How Eco-Clarity Works

Eco-Clarity has created a patented technology solution that easily collects and separates fat, oils and grease (FOG) from waste water through an efficient and fully automatic hub system made up of three scalable containers.

The system enables FOG to be separated before it enters the water system and becomes problematic. The cleaned water is then reused or safely returned to the waste stream. In turn, the successfully separated FOG becomes a sustainable raw material that can be used to produce second-generation biodiesel – feedstock for energy recovery in the UK and EU, which qualifies for triple counting renewable energy directive (RED) credits.

The oil recovered goes up from 5% to +95% concentration after going through the Eco Clarity system, turning it into a valuable raw material for biodiesel production.

Eco Clarity is transforming the wastewater disposal process by extracting a valuable raw material whilst improving the quality of the separated water for reuse or for conventional treatment.

A standard Eco Clarity hub can handle 10 tons of FOG containing waste water in 10 minutes, which can then go on to begin separation immediately, and begin harvesting within 30 minutes. The hub’s efficient system currently uses just 25% of the energy typically used in similar processes, with temperatures never exceeding 60 degrees to ensure low energy consumption.

Eco Clarity is focused on revolutionising the way wastewater is handled by turning the process from one of disposal, into one of conversion into effectively clean water, by filtering out beneficial oil residues which can then be used as raw material for the production of biodiesel – a sustainable alternative to fossil fuel, which can reduce GHG (Greenhouse Gas) emissions by around 90%, directly impacting the world’s carbon footprint.

Recent Comments